PRODUCTS

GRAVURE ROLL

NEW EXPERIMENT SOLUTION TECHNOLOGY

Carbon Roll

Carbon Guide Roll (Patent No. 10-1253727)

Carbon guide roll boasts outstanding elasticity and strength thanks to the ultra-light carbon material and ensures light weight, high strength, and high-risk rotation numbers. Mainly used for surface finishing of liquid crystal, film, printing, and paper, it prevents creases and reduces defect rate, thereby, improving product quality.

-

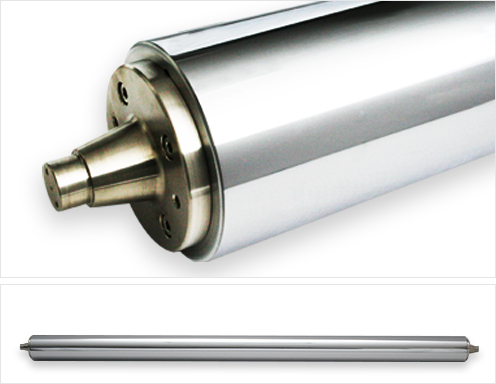

Tubing Plating Polishing Carbon Roll

-

Rubber Sheath Carbon Roll

Features

- Like conventional metallic rolls, it can be used for surface finishing of various types of products

- Hcr (chrome), nickel plating, etc.

- Crown and reverse crown, grove fabricating

- Various types of rubber lining

- Ceramic solvent

- It has a micron(㎛)-level of roll rotation precision

- High precision level created by ultra-high speed rotation

- Strong heat resistance

- Controls imbalanced thermal expansion at high temperature

- Metal sleeve material

- SUS, A/L

-

Metal end

membersCarbon pipe

(CFRP)Metal sleeve

Specifications

| Classification | SUS and A/L tubing plating polishing roll | Rubber lining roll |

|---|---|---|

| External diameter (Φ) | Φ50 to Φ180 or larger | Φ140 to Φ180 or larger |

| Whole length (mm) | MAX 3,500mm | MAX 6,000mm |

Precision

| Out of roundness / Straightness | surface roughness (1st, 2nd plating polishing) | Plating thickness (micron) |

|

|---|---|---|---|

| Polishing | Super finishing | ||

| ±1/100mm or less | 0.3S or less | 0.2S or less | 100㎛ ~ 150㎛ |

Comparison of guide roll production by material (distributed load 20kg/m)

| Material | External diameter(mm) | Bore(mm) | Length(mm) | Weight(Kg) | Bending(mm) | Moment of inertia(Kg.㎡) | Rotational speed(m/min) |

|---|---|---|---|---|---|---|---|

| Steel | 140 | 130 | 2,000 | 43 | 0.08 | 0.72 | 1,010 |

| Aluminum | 21 | 0.16 | 0.32 | 1,000 | |||

| Carbon | 17 | 0.06 | 0.24 | 2,330 |